Project

The aim of the project, which was carried out with students in the summer semester 2019 in the Robots in Architecture seminar, was to symbiotically link human skills and digital methods on three levels – architectural design, digital manufacturing and construction.

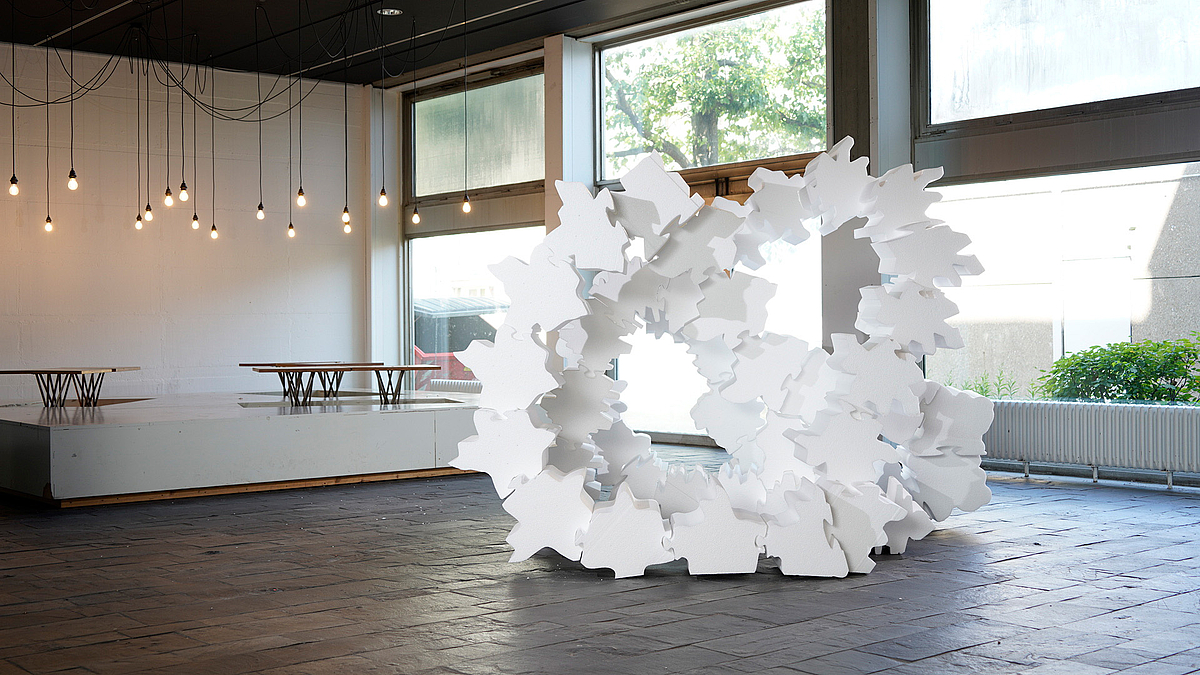

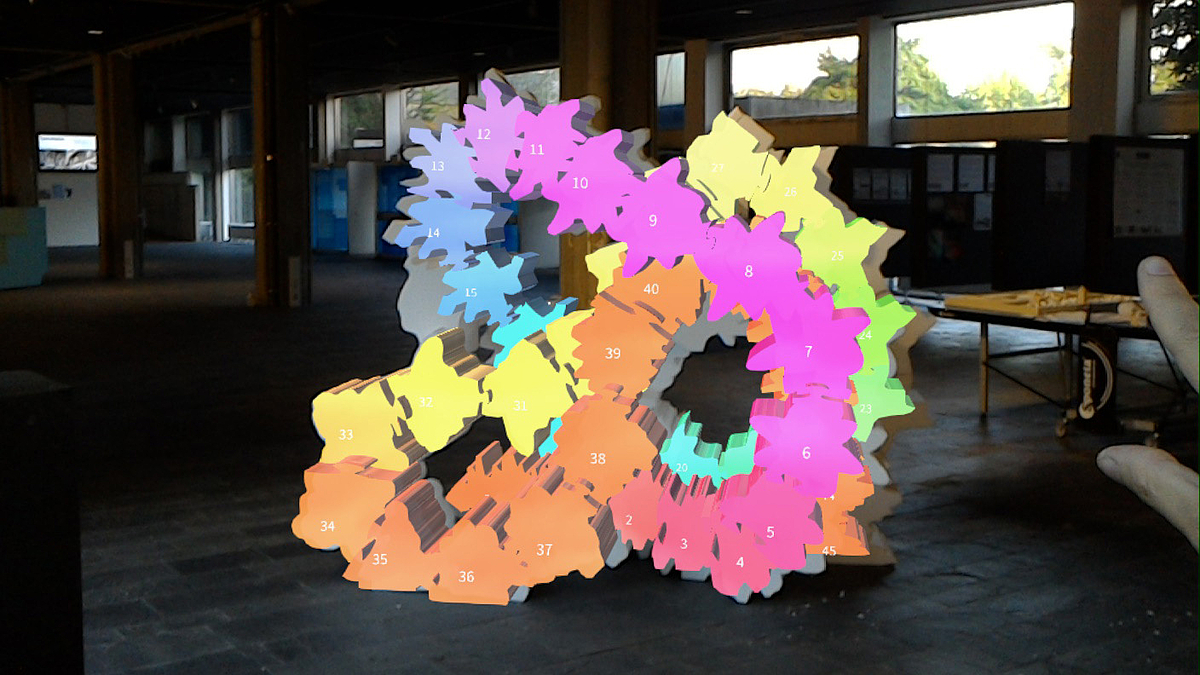

Digital design methods today can easily represent complex geometries and generate manufacturing data from them for different numerical manufacturing methods, such as CNC milling, 3D printing or robotic pick and place methods. An obvious gap in the chain of digital processes from design to built artefact is still the on-site assembly, as a large number of very different elements have to be installed in a specific sequence at a given position. This gap was given special attention in the following project by investigating the use of augmented reality headsets to assemble the 45 different elements.

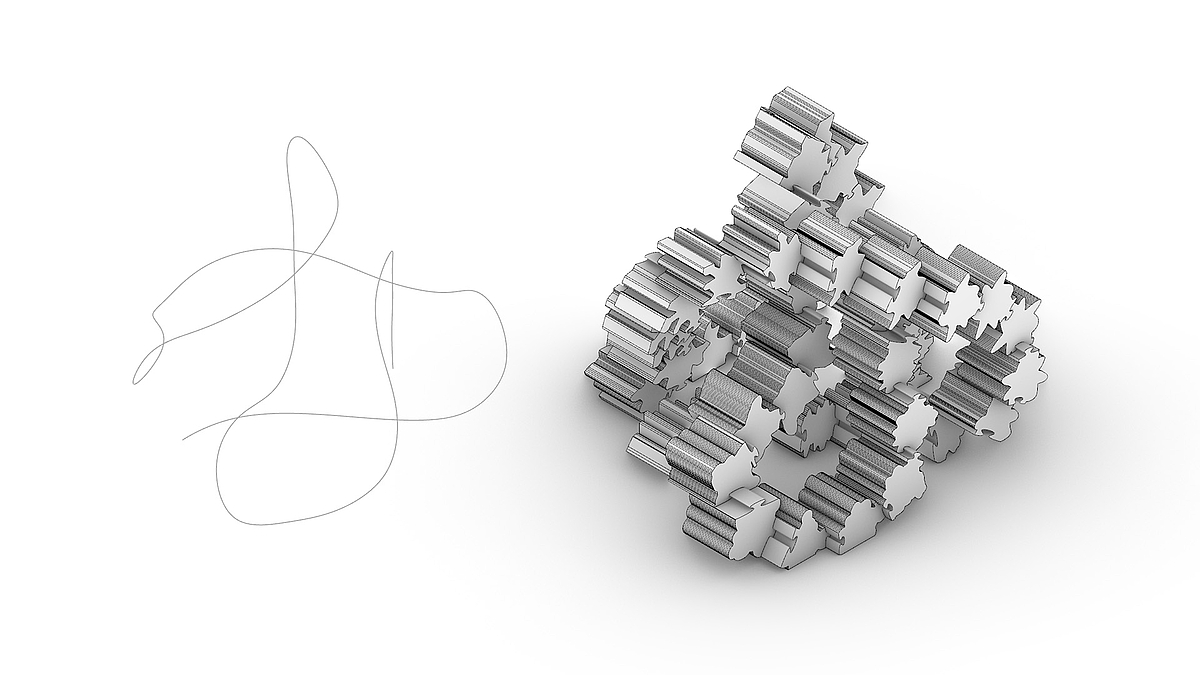

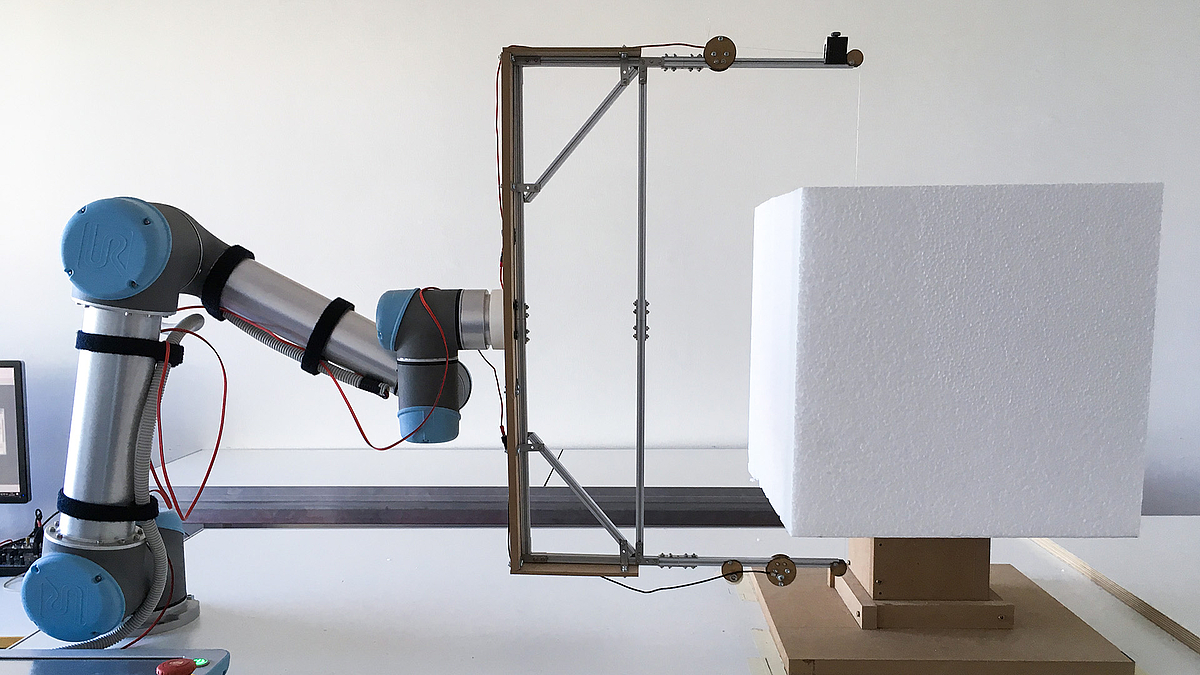

The design was generated along a spatial curve that emerged from the recording of human movement and was based on an analysis of the works of the choreographer Willian Forsythe. Along this curve extruded blocks are distributed that are structurally interlocked, allowing them to be cut using a robotic hot wire tool.

The blocks were fabricated in rigid foam from data, derived directly from the design model using a UR-5 robotic arm. For assembly, the Microsoft HoloLens AR headset was used with Fologram software, which generated a visual overlay for the assembly from the design model to guide manual joining.

This approach of supporting the assembly of generative designs with AR has proven successful in this first demonstrator and will be further pursued in research and teaching.

Info

Project Leader:

- Victor Sardenberg

- Andrea Kondziela

Participants:

- Elena del Cura Beryal

- Anna Koyachkova

- Thuz Dinh

- Shan Wang

- Yamin Stev

- Kamilla Zambo

Material Sponsor:

JET Schaumstoff-Formteile GmbH